Eliko UWB RTLS

Accurate

Reliable 10-50 cm tracking even in complex environments. Gets the same result with less devices.

Reliable

Robust in challenging non-line-of-sight environments, indoors and outdoors.

Real-time

Down to 10 ms latency and two-way communication for safety and other demanding applications.

Flexible

Open APIs for integration & configurations to suit various use cases.

Trusted by

The Eliko UWB RTLS has been developed in close cooperation with our customers and partner since 2014. It has been validated by hundreds of innovators worldwide in challenging environments, both indoors and outdoors. As a backbone of mission-critical applications, Eliko’s precise positioning networks provide transparency, efficiency and safety across industries worldwide.

Benefits of Eliko UWB RTLS

Accurate

Eliko UWB RTLS is the most accurate on the market as a result of using the AP-TWR UWB protocol. It combines active and passive measurements and provides up to 8 x more data points with every positioning.

The RTLS is designed for reliable 10-50 cm tracking or sub-1 metre networks in 2D or 3D in complex environments. In specific cases a 5 cm/2 inch accuracy is possible. The system uses a combination of hardware and custom algorithms designed and optimised in-house.

Reliable

Eliko UWB RTLS software provides robust and reliable localisation by combining unique algorithms for coordinate calculation, roaming, and network monitoring. This is a result of 5+ years of development and working in industrial environments.

On the low level, UWB radio itself has superior performance in multipath and reflections, penetrates obstacles and has no interference issues with other radio waves compared to BLE or Wi-Fi.

Tailored to your needs

Eliko RTLS adapts to your needs. We have designed the system to be flexible on every layer. The system supports accuracies from cm-level down to 1-anchor based proximity, refresh rates up to 75 Hz, and special tracking modes for solving use cases that others cannot.

Eliko’s advanced distance-based system enables to scale the network by just adding anchors to the network. No time synchronizations or calibration are needed.

Cost-efficient

We ensure that you get a reliable positioning network with a fair value. Eliko RTLS enables to track objects with up to 3 x less hardware, using the AP-TWR protocol. This lowers the initial installation and maintenance costs.

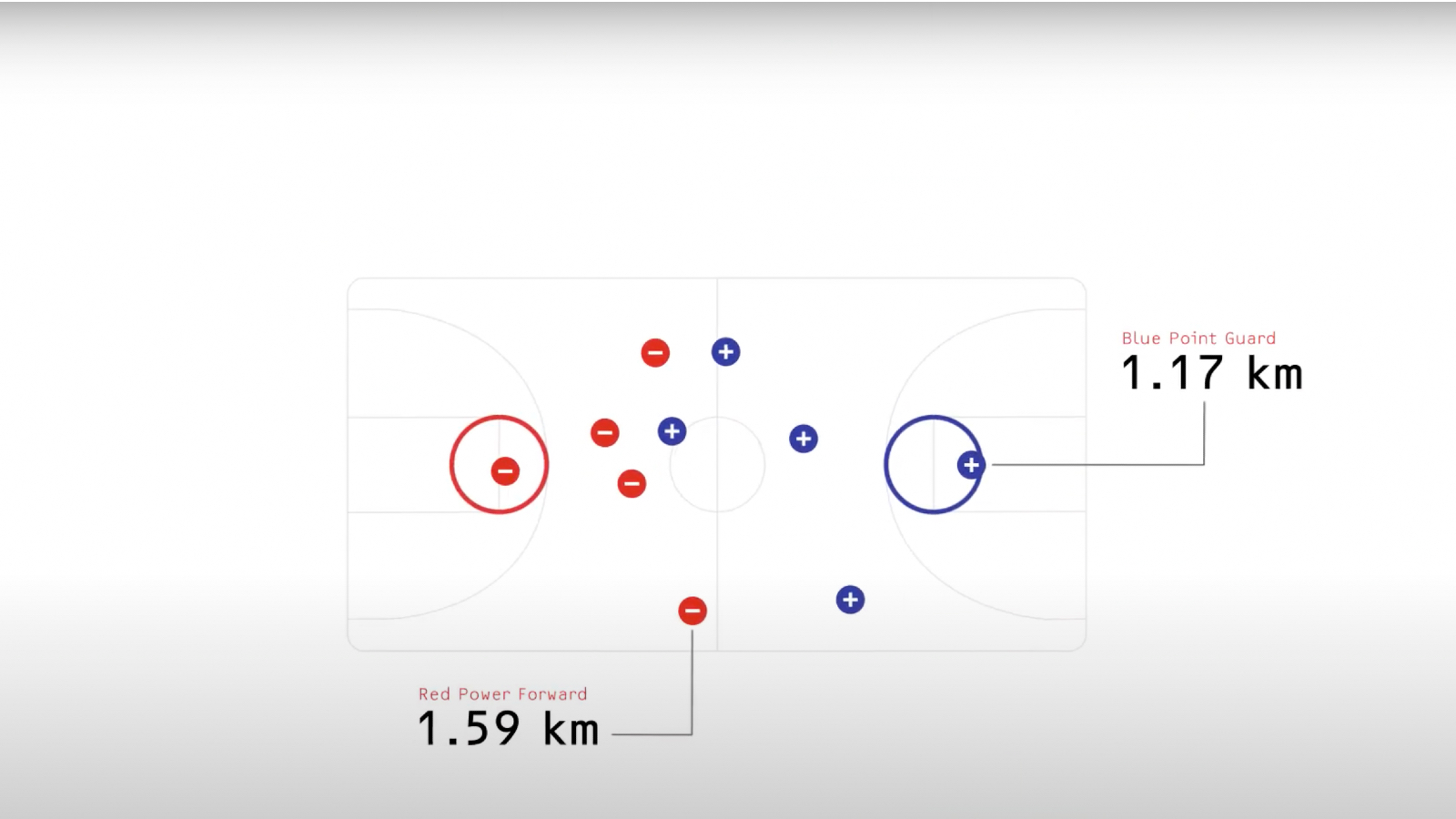

How it works

Watch our introductory video about how the Eliko UWB RTLS works.

The Eliko UWB RTLS system consists of anchors, different tags, RTLS Engine and RTLS Manager softwares. The mobile tag uses ultra-wideband radio technology to communicate with the anchors that are placed around the tracking area. The tag chooses anchors based on self-learning algorithms from which the distances are calculated. Based on the distances measured, the coordinates are calculated in the server using state-of-the-art self-learning algorithms.

System components

Key components of the Eliko RTLS system are anchors, tags, and the RTLS software. Here is a short introduction to the system.

Tags

Tags are small mobile devices which enable you to track anything or anyone with an update rate from once per minute up to 100 Hz.

- Personnel tag – compact devices with battery life up to 5 months, accelerometer, IP52 (IP67 on request)

- Asset tag – IP67 casing and battery life up to 5 years, 6-DoF IMU optional

- Vehicle tag – IP67 casing, custom cables, 6-DoF IMU optional

- Configurable LED lights, vibration motor and external devices for alarms and notifications

Eliko RTLS Software

The Eliko RTLS Software is where the data from the anchors becomes a reliable coordinate across the tracking area. The software enables to also configure devices, build business rules –

- Create zones, events, notifications & alarms based on zones

- Proximity, 1D, 2D, 3D tracking

- Connect objects to tags, track objects across indoor-outdoor areas

- Location calculation using advanced ML algorithms and filtering

- Advanced network management and adaptable configurations

Eliko RTLS Manager

The Eliko RTLS Manager is an easy graphical user interface to provide a clear overview of the system.

- Enables to speed up the system setup

- Configuration of anchors and tags

- Real-time visualisation of the tracking area

Optional Add-ons

We use the following add-ons to set up the system:

- USB charging dock

- Different mounting options for tags and anchors

- LED accessories for tags

- Bracelet

Key features

Choose an accuracy level

You can set up the system based on your accuracy needs starting from 5-10 cm down to room-level proximity. Accuracy is subject to anchor count: increase or decrease the density of anchors based on your accuracy needs and environment.

Set update rates

You can set suitable update rates for your tags from once per minute up to 75 Hz (Hz- times per second). The system enables you to set different update rates for standing and moving.

Create geofences

The geofence feature enables you to create digital zones around moving objects and people or static areas. So you can use the system for applications that keep employees safe by creating digital safety zones and anti-collision systems. Geofences also enable you to trigger other events, such as stopping a machine or sending a notification about an arrival at the production area.

Trigger events

You can use the tags for applications where you need to trigger real-time notifications. For example, send alarm notifications to tags to flash LED on the tag, to make the tag vibrate or to trigger external devices. With its two-way communication and absolutely lowest latency, Eliko UWB RTLS is suitable for demanding applications.

Configure through API

The system’s API friendliness makes it ideal for developers demanding flexibility. Eliko offers both NMEA-based communication protocol as well as REST API for fast deployment. Contact us for the details and API documentation.

Customise

Do you have specific needs? We have customised the standard hardware, software, data output, integration and much more for various verticals with specific needs. Contact us at and let’s discuss it.

Piloting with Eliko RTLS

Rent a RTLS kit from us to build your use case or test your application. The kits contain:

- 6 pc Eliko RTLS Anchors

- 4 pc Eliko RTLS Personnel Tags

- 1 pc Eliko RTLS Ranging & Manager software licenses

- 1 pc Supermicro SuperServer E100-9AP

- 1 pc 4- or 8-port PoE Switch

- Technical support & solution consulting

Minimum duration: 1 month.

Case studies

“We studied several real-time tracking systems with different technologies and, in the end, we decided to implement the UWB RTLS from Eliko. For us, it had the best location tracking results, the easiest configuration and the best cost-efficiency ratio.”

“We did tests with Eliko’s UWB RTLS and compared it with other similar solutions on the market. Based on our test results we are confident in recommending the TWR-based Eliko RTLS solution as a robust UWB solution.”

“Eliko has proved to be on top of the competition in the RTLS domain, and its technical and sales force personnel have always been available when needed.”

“The RFID simply gave us wrong measurements, and we wanted the best when it comes to accuracy and flexibility. Eliko’s UWB RTLS system met our technical needs and was easy to understand. We had a good support from Eliko’s team and they assist us well to set up the system, including the anchors.”

“Eliko were a pleasure to work with. They were proactively supportive and always conscious of our needs. Their responsiveness despite the time zone difference of their headquarters made a huge difference in our ability to painlessly implement their technology. Their product is exceptional, but their commitment to supporting our work was what really allowed our experiences to shine.”

How to start

From solution consultation, network design and installation to maintenance – we support your projects from one end to the other and as much as you need. We provide global support from South and North America to Europe and Australia.

Solution consultation

Every partnership starts with a consultation to analyse the feasibility of the technology for your specific use cases.

Technical proposal

As a next step, we provide you with recommended radio planning, keeping in mind the most optimal solution for your use case and tracking environment. The proposal includes a detailed budget estimation.

Radio network planning

The final anchor locations depend on the use case and internal restrictions. We help plan your communication network to support the tracking system and determine the final radio plan.

Installation

We guide you through the installation step by step and help configure the system remotely.

Project handover

We verify that the tracking system fits your needs and hand it over to your team.

Ready to innovate? Get in touch

Frequently asked questions

The number of anchors you need to cover the tracking area heavily depends on the environment of the area, as conditions are rarely ideal. Therefore, we cannot guarantee any one-size-fits-all rule. The best way to find out the approximate number of anchors needed for your tracking area is to contact our RTLS experts and provide us with the floorplan of the area and some pictures if possible. The preliminary setup for tracking can then be drafted based on the information provided.

In general, for 2D positioning, the minimum number of anchors needed is 3. However, we recommend 4 anchors for additional reliability and optimal precision. For 3D positioning, at least 4 anchors are required. With 4 anchors you can cover about 50×50 m (~2500 m2) in ideal conditions. In a difficult non-line-of-sight (nLoS) situation more anchors are used to provide the best precision possible. If your layout does not allow a standard easy setup, contact us for guidance.

Like Bluetooth and Wi-Fi, ultra-wideband (UWB) is a short-range, wireless communication protocol that operates through radio waves. But unlike its counterparts, it operates at very high frequencies — a broad spectrum of GHz frequencies — and can be used to capture highly accurate spatial and directional data.

Eliko RTLS, which uses ultra-wideband (UWB) radio technology, works both indoors and outdoors. Therefore, while primarily an indoor positioning system, it is also suitable for temporary outdoor applications. The Wi-Fi anchors enable the quick and convenient setup of the system without having to worry about cabling.

For permanent outdoor installations, UWB regulations should be checked, as such installations may be prohibited depending on the country or region. Learn more about the current status of regulations from UWB Worldwide regulations or contact us for in-depth information about UWB regulations.

The required level of water resistance should also be considered when planning an outdoor application.

We ensure that you get a reliable positioning network with a fair value. Eliko RTLS is based on a unique UWB design that enables us to optimise the anchor count. Additionally, we can combine multiple positioning methods in different places of the tracking area. As a result, with the Eliko UWB RTLS system you may need up to half the infrastructure hardware than is typical to ensure the precision you need. This also lowers the installation and maintenance costs. The infrastructure costs start from 2 EUR per m2, depending on the tracking environment and accuracy needs.

TWR – two way ranging

TDoA – Time difference of arrival.

Both the TWR and TDoA methods rely on measuring the time it takes for the radio waves to travel a certain distance in the air. The difference lies in the distances we actually measure and how we use them to calculate the position of the tag.

Read more about their pros and cons on our blog post:

Eliko is shaping the future by developing next-generation positioning networks for digital solutions that depend on location data.